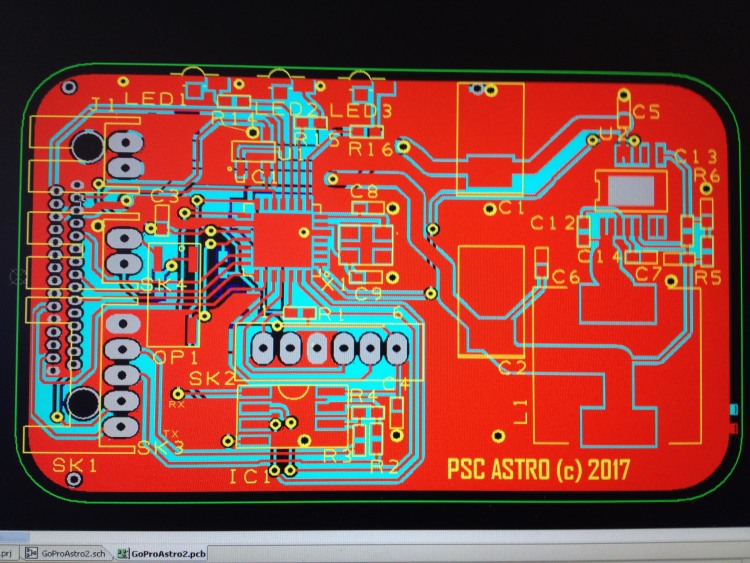

Custom Electronics

Should you have a requirement for a custom electronic or mechanical item for a production or facility I am happy to discuss the design and cost without obligation.

I offer microprocessor (PIC and ATMEL) software development and digital and analogue circuit/PCB design and build capability for prototype's or one-off production. Designs can incorporate motor drivers, LED's, displays, controls, encoders, video, audio, wireless and radio from microwatt to kilowatts.

I can do limited mechanical work in aluminium and plastics using small CNC routers , lathes and laser cutters/engravers. This includes custom controllers and grip equipment (i.e. telephoto lens mount, camera grips, action buttons).

Custom Design and Prototypes

The item can normally be started with a prototype build ready for software and control testing within days.

This helps the customer to evaluate the function and form rapidly. If the requirement is complex or requires heavy outlay from the start it is normally agreed to pay a development fee upfront.

Many custom designs are a one-off type designed to fulfill a temporary requirement or to build a prototype for further development. If it is decided to build a number of items for onward sale or export then one must insure that the product meets safety standards for the expected market and EMC (electro magnetic compatibility) requirements by having the product tested in approved labs and certified (CE for Europe and FCC for US).

It is also a factor that custom built products will be built to meet such standards from the first design stage and you should insure that due care is being observed in this regard as any changes required at a later stage may incur further costs and testing.

Costs

It can be a surprise to find the cost of a custom built item is often many times more expensive than first thought. This will be due to a number of factors. Firstly, the construction may require a resource which is not available to the company (i.e. a CNC machine, a specialist tool, testing equipment), Secondly, the company will have to procure the parts to build the prototypes and in many cases must buy multiples of a part (i.e. a bag of 100 screws when only 4 are required, 100 metre of cable when only 10 metres are required).

Design Stages

The project is broken into a number of stages:

- Design brief requirements and a budget

- Design plans and costings produced

- Hardware build

- Software build

- Parts procurement

- build and test

- build and test (yes, maybe several times !)

- Customer test

- Completion, In service.